With the continuous development of China’s power grid and the urbanization level rising, in the process of power grid construction of underground cable is gradually replacing overhead transmission lines, along with the advancement of urbanization, the total length of cable will increase year by year, how to improve the cable line power supply reliability, and guarantee the safe and stable operation of power system, and to reduce power losses and manpower material resources, It has become an important topic of cable line operation and maintenance management.

China’s current use of 35K V large cross-section power cables and 66K V, 110K V and above voltage level of power cables are single-core cable, cable metal sheath one end of three-phase interconnection and connection to the ground, the other end is not connected to the ground, when the lightning wave or internal voltage along the cable core flow, Cable metal sheath ungrounded end will appear high impact overvoltage phenomenon, or when the system short-circuit accident occurs when the current flows through the cable core, the sheath ungrounded end will also appear high power frequency induction overvoltage phenomenon. In the above situation, voltage may directly pass through the insulation equipment of cable outer sheath, resulting in multi-point grounding fault of cable metal sheath, which seriously affects the normal operation of power cable and even greatly reduces the service life of cable. Therefore, according to the current electric power industry standard DL/T401-2002 “Guide for Selection of high voltage Power Cable”, cable sheath protector should be used to better limit the induction voltage and fault overvoltage generation on the metal sheath of power cable.

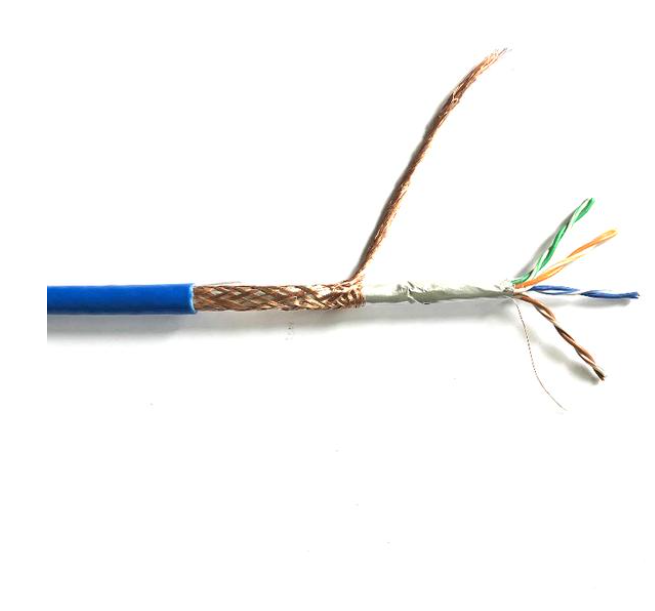

In the current ac transmission system consisting of single core cable in China, the metal shield of power cable must be grounded. In the long-distance construction process of the single-core power cable, the cable line shall be constructed in multiple sections, and the metal shielding layers shall be cross-connected with each other. At the same time, the metal shielding layers of the three-phase cable shall be continuously transposed to achieve the sum of the potential vector of the symmetrical metal shielding layers of the three-phase cable to be zero. Cross-connected grounding box is an effective grounding protection method to solve the above problems.

Cable sheath cross interconnection protection grounding box is a kind of cable sheath grounding device, the most important purpose of which is to effectively control the influence of inductive voltage and fault overvoltage on the cable metal sheath, and reduce the circulation problems in the sheath. The two ends of the cable metal cover are divided into protective grounding and direct grounding. However, when the cable line is relatively long, the cable cover should be divided into three sections for mutual insulation and effective grounding after cross-connecting and passing through the protection device.

At present, there are two main installation methods of transmission cable sheath cross-interconnection protection grounding box. The first method is to set the installation grounding box independently on the ground near the intermediate joint well, lead the grounding wire of the cable middle joint to the grounding box for wiring, and install the protection shell and protection bar outside the grounding box. This installation method can be waterproof and moistureproof, convenient operation and maintenance personnel at any time to open the ground box operation, but because the cable is buried on both sides of the streets of the town, the ground box and the protective bar after the appearance is larger and installed on the ground, easy to block to the facade by nearby merchants or residential residents of the opposition and obstruction.

(As shown in FIG. 1) The second method is to install the grounding box in the intermediate joint well when a suitable position cannot be found on the ground near the intermediate joint well for independent installation (or blocked by external factors). But because there is no good waterproof sealing performance of the grounding box, most of the grounding box installed in the well in the operation of a period of time will be affected by moisture in different degrees, resulting in the grounding wire and other metal parts inside the box rust, fever and even brittle broken; And because it is installed in the middle well, when it is necessary to open the ground box for operation, it is necessary to open the cover of the middle well first. The manhole cover is bulky and difficult to open, which often requires a certain amount of human energy and delays the operation time.

Post time: Jul-07-2022