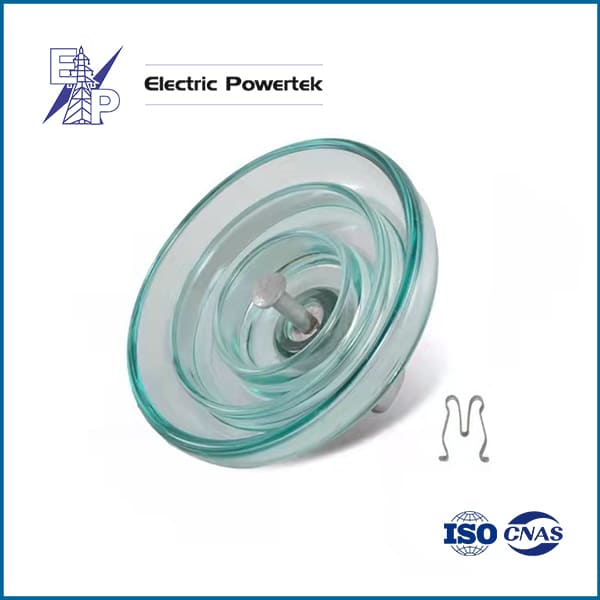

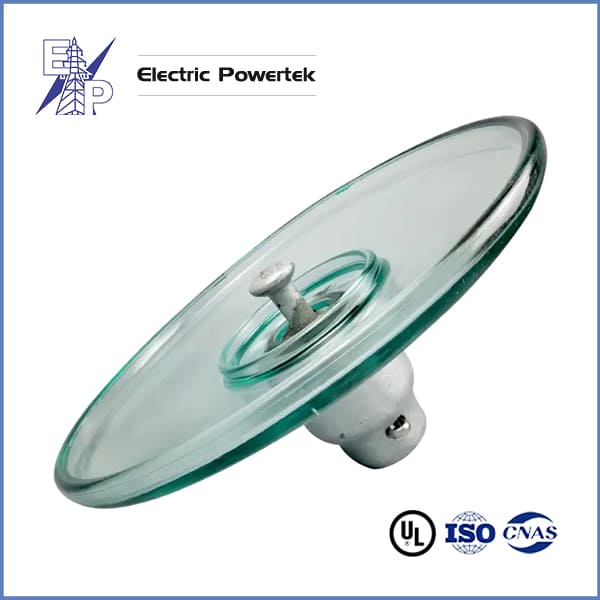

Antifouling Type Disc Suspension Toughened Glass Insulator

Product Description

Insulators are devices used to support and insulate electrical wires. The insulator device is made of toughened glass and is called a glass insulator; Currently, toughened glass insulators are the most widely used in power lines.

|

Product name

|

Glass insulator

|

|

Type

|

Antifouling insulator |

|

Material

|

Toughened glass

|

|

Scope of application

|

High voltage

|

|

Usage

|

Support wire

|

|

Application

|

Overhead transmission line

|

|

Standard

|

IEC/ISO |

Specification

| Model Number | Diameter

(mm) |

Structure

Height (mm) |

Creepage

Distance (mm) |

Coupling

Size (mm) |

Mechanical

Failing Load (kN) |

Mechanical

Routine Test (kN) |

Power

Frequency Wet Withstand Voltage (kV) |

Lightning

Impulse Withstand Voltage (kV) |

Puncture

Voltage (P.U) |

Power

Puncture Voltage (kV) |

Radio

Interference Voltage (μV) |

Corona

Test (Pin&cap) (kV) |

Power

Frequency Arc Teat |

Net

Weight Per Unit (kg) |

||

| Model Number | LXHY Series | FC Series | ||||||||||||||

| U70BP/146 | LXHY4-70 | FC7P/146 | 255 | 146 | 400 | 16 | 70 | 35 | 45 | 110 | 2.8 | 130 | 50 | 18/22 | 20kA | 4.6 |

| U70BP

U70BP/146 |

LXHY5-70 | FC70P/146 | 280 | 146 | 450 | 16 | 70 | 35 | 50 | 125 | 2.8 | 130 | 50 | 18/22 | 20kA | 5.8 |

| U70BP/146 | LXHY6-70 | FC70P/146 | 320 | 146 | 550 | 16 | 70 | 35 | 55 | 140 | 2.8 | 130 | 50 | 18/22 | 20kA | 6.1 |

| U100BP/146 | LXHY-100 | FC10P/146 | 255 | 146 | 400 | 16 | 100 | 50 | 45 | 110 | 2.8 | 130 | 50 | 18/22 | 20kA | 5.2 |

| U100BLP

U100BP/146 |

LXHY4-100 | FC100P/146 | 280 | 146 | 450 | 16 | 100 | 50 | 50 | 125 | 2.8 | 130 | 50 | 18/22 | 20kA | 5.9 |

| U100BP/146 | LXHY5-100 | FC100PL/146 | 320 | 146 | 550 | 16 | 100 | 50 | 55 | 140 | 2.8 | 130 | 50 | 18/22 | 20kA | 8.2 |

| U120BP/146 | LXHY-120 | FC12P/146 | 255 | 146 | 400 | 16 | 120 | 60 | 45 | 110 | 2.8 | 130 | 50 | 18/22 | 20kA | 5.3 |

| U120BP

U120BP/146 |

LXHY4-120 | FC120P/146 | 280 | 146 | 450 | 16 | 120 | 60 | 50 | 125 | 2.8 | 130 | 50 | 18/22 | 20kA | 6.0 |

| U120BP/146 | LXHY5-120 | FC120PL/146 | 320 | 146 | 550 | 16 | 120 | 60 | 55 | 140 | 2.8 | 130 | 50 | 18/22 | 20kA | 8.3 |

| U160BP

U160BP/155 |

LXHY3-160 | FC16P/155 | 280 | 155 | 450 | 20 | 160 | 80 | 50 | 125 | 2.8 | 130 | 50 | 18/22 | 20kA | 7.0 |

| U160BP/170 | LXHY4-160 | FC16P/170 | 280 | 170 | 450 | 20 | 160 | 80 | 50 | 125 | 2.8 | 130 | 50 | 18/22 | 20kA | 7.1 |

| U160BSP

U160BP/146 |

FC160P/146 | 320 | 146 | 550 | 20 | 160 | 80 | 50 | 125 | 2.8 | 130 | 50 | 18/22 | 20kA | 8.8 | |

| U160BLP

U160BP/170 |

LXHY5-160 | FC160P/170 | 320 | 170 | 550 | 20 | 160 | 80 | 55 | 140 | 2.8 | 130 | 50 | 18/22 | 20kA | 9.1 |

| U160BP

U160BP/155 |

LXHY6-160 | FC160P/155 | 320 | 155 | 550 | 20 | 160 | 80 | 55 | 140 | 2.8 | 130 | 50 | 18/22 | 20kA | 9.0 |

| U210BP

U210BP/170 |

LXHY3-210 | FC210P/170 | 320 | 170 | 550 | 20 | 210 | 105 | 55 | 140 | 2.8 | 130 | 50 | 18/22 | 20kA | 9.6 |

| U240BP/170 | LXHY-240 | FC240P/170 | 320 | 170 | 550 | 24 | 240 | 120 | 55 | 140 | 2.8 | 130 | 50 | 18/22 | 20kA | 9.9 |

| U300BP

U300BP/195 |

LXHY-300 | FC300P/195 | 320 | 195 | 550 | 24 | 300 | 150 | 55 | 140 | 2.8 | 130 | 50 | 18/22 | 20kA | 11.3 |

The advantages of glass insulator

1 The raw materials used to manufacture glass insulators, in terms of their own composition, are more stable than those used to manufacture electric porcelain, creating good conditions for stabilizing the electrical and mechanical properties of glass.

2 Due to the transparency of glass, it is easy to detect small cracks and various internal defects and damages during appearance inspection.

3 The mechanical and electrical performance of tempered glass is much higher than that of porcelain, making insulators of the same type, and its size and weight are much smaller than porcelain insulators.

4 The mechanical strength of the surface layer of glass insulators is high, and the surface is not prone to cracks. The electrical strength of glass generally remains unchanged throughout the entire operation period, and its aging process is much slower than that of porcelain. Therefore, glass insulators are mainly scrapped due to self damage and occur within the first year of operation. However, defects in porcelain insulators only begin to be discovered after a few years of operation.

5 By using glass insulators, regular preventive tests on insulators during operation can be cancelled. This is because every type of damage to tempered glass can cause damage to the insulator, and operators can easily detect it during line inspections. When the insulator is damaged, the glass fragments near the steel cap and iron foot are stuck, and the mechanical strength of the remaining part of the insulator is sufficient to prevent the insulator string from breaking off.

Insulation Resistance Measurement Of Insulators

(1) The purpose of measurement is to check the insulation condition of insulators and discover defects such as insulation degradation and insulation breakdown.

(2) It is recommended to use a 5000V megohmmeter for measuring the insulation resistance of insulators on 35~220kV overhead transmission lines.

(1) The insulation resistance of newly installed insulators should be greater than or equal to 500M Ω.

(2) The insulation resistance of insulators during operation should be greater than or equal to 300M Ω.

(1) Insulators with insulation resistance less than 300M Ω and greater than 240M Ω can be considered as low value insulators.

(2) Insulators with insulation resistance less than 240M Ω can be considered as zero value insulators.

(1) Temperature has a significant impact on insulation resistance, which decreases with increasing temperature. The reason is that the temperature increases, the polarization of the insulation medium intensifies, and the increase in conductivity leads to a decrease in insulation resistance. The reason for the change is related to the degree of temperature change and the properties and structure of the insulation material.

(2) Humidity has a significant impact on surface leakage current, as it adsorbs moisture on the insulation surface, forming a water film that significantly reduces insulation resistance.

(3) Degradation caused by mechanical overload of insulators.

(4) Deterioration of moisture absorption of porcelain parts.

(5) Deterioration of internal and external stress overlap in porcelain components.

(6) Deterioration caused by thermal expansion of porcelain insulators.

(7) Deterioration of saturated expansion of steel cap pouring cement.

(8) Deterioration of freezing and expansion properties of steel cap pouring cement.

(9) Deterioration of electrical corrosion of steel caps and feet.

(10) Deterioration caused by overvoltage of insulators.

(11) Deterioration caused by internal defects in insulators.

Attention for measuring insulator resistance: When the humidity is high, the measurement should be suspended.

For single component insulators, the insulation resistance can only be measured in the event of a power outage. According to relevant regulations, a 2500V and above megohmmeter is used. The commonly used ones are 2500V and 5000V megohmmeters, as well as specialized instruments with higher voltages. But in fact, within 1 * 104M Ω, insulation resistance measured by 2500V and 5000V megohmmeters with the same accuracy at the same humidity is basically the same. When the measured insulation resistance is greater than 1 * 104M Ω, the 2500V megohmmeter cannot read the accurate insulation resistance value and can only count it as ∞. A 5000 megohmmeter can achieve a maximum insulation resistance of 2 * 105M Ω.

For insulators with multiple component combinations, the insulation resistance can be measured with power off or live. The method is to connect a high resistance to a live insulator, so that the megohmmeter for measuring insulation resistance is at ground potential, and subtract the high resistance value from the measured insulation resistance to obtain the insulation resistance value of the tested insulator. The principle wiring for measuring the insulation resistance of insulators with electricity, where R is the resistance in the high resistance pole, with a resistance value of 10-20k Ω/V and a length of 0.5-105kV/cm, and a unit resistance capacity of 1-2W; C is the grounding capacitance, which can keep the megohmmeter at ground potential. The insulation resistance of C should reach the maximum limit of the megohmmeter to ensure measurement accuracy. The capacitance of C ranges from 0.01 to 0.05 μ F. It should be able to withstand DC voltage above 3000V.

(1) The resistance of each component and suspension insulator of the pin type post insulator should not be less than 300M Ω.

(2) The insulation resistance of 500kV suspension insulators shall not be less than 500M Ω. It is worth noting that when measuring the insulation resistance of each component of a multi component post insulator, copper wire should be wound at the laminated bonding point and then connected to a megohmmeter to avoid significant differences in insulation resistance values measured at different positions, which may cause misjudgment.

Application

Glass insulators are mainly used to fix wires to poles and insulate them from poles. Insulators are one of the key components of high-voltage transmission lines, and their performance directly affects the operational safety of the entire transmission line. Glass insulators are widely used due to their characteristics of zero self breaking and easy maintenance.